Back to School – Retail Sales & Inventory Reporting

By Jim Lewis, CEO Increased Retail Solutions LLC

I lately experienced the honor of lecturing at my alma mater, the University of Florida. We discussed the basic principles of retail analytics, the resources and roles of retail and wholesale stock planners. We talked about how merchandise choices are made to hopefully make magic on the income ground. But the magic does not generally take place.

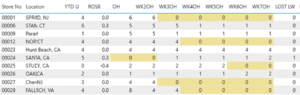

A college student questioned what results in a store to have vacant cabinets. Which is a complete lecture within just alone. We talked about some of the factors- what can be managed and what can not. They know what they read- that the pandemic induced havoc on the source chain. While that is genuine, there are many other triggers, specially now that the supply chain is easing. We targeted on studying the mechanics of how out of shares consequence in dropped gross sales. Just one of the experiences I showed the inventory of an merchandise by retailer by 7 days, highlighting when it was out of stock. Pupils speedily did the math to determine out how much income was remaining left on the desk.

Observe inventory by sku by week by retail store to uncover outs and shed chance.

Predicting Out of Shares

Though there are some retailers whose philosophy is that they’d rather be out of inventory than mark down an item, the huge the greater part don’t want to be out of stock. Protecting against inventory outs requires a whole lot of going elements to sync harmoniously. There have to be a regular movement of inventory coming from the wholesale side with peaks and lulls taken into thought. The allocation approach depends extremely a great deal on the sophistication of the retailer. Some automobile replenishment systems only stick to a minimum quantity, some add price of sale to that, but most are not wise ample to prioritize retailers and goods that are out the most. And quite a few really don’t increase back missing product sales, which usually means the complete basis for the forecast does not reflect the true probable. Then there is the sheer volume of sku’s- millions of sku-retail store mixtures to deal with.

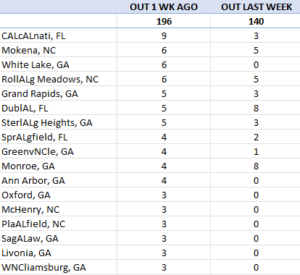

Continue to keep monitor of the stores or products that are regularly out of inventory.

VMI

The most effective system for being in inventory is VMI (Vendor Managed Stock) where by the retailer employ’s their supplier’s means to forecast and make certain merchants continue to be in inventory. It basically suggests these sku’s will have much more aim on them than non-seller managed items. This focus allows the supplier laser focus on suppliers and sku’s that are most possible to go out of inventory, and beef them up.

Eventualities

Even with the greatest of intentions, there might not be sufficient inventory or open to buy to allocate in the most efficient method. That is why documenting eventualities is significant. If you only have so quite a few assets- which stores or items gets fed very first? What gets prioritized? Or does every single keep get a more compact total? These may perhaps change relying on the condition, but we recommend acquiring a “play book” so there is a approach in place.

Information Science

It actually isn’t mind science. We have an abundance of reviews and methods that frequently study which goods and outlets are sold out- so that stock can be prioritized to take care of the difficulty. Dependent on a blend of knowledge details- wholesale stock movement, historic store and item inventory outs, seasonality, promotions, etcetera., we use a number of very simple algorithms to do the perform. It does call for impressive computing electricity to sift by way of millions or billions of documents of data, so it is not for the faint at coronary heart.

I normally enjoy speaking to college students. At its heart, ERS was launched on education- instructing suppliers to imagine and act like suppliers. It has advanced into considerably additional in excess of the final 20 many years, but training remains a main focus of our business.

For a lot more details, contact us.